Rebar is mostly a fundamental metal bar or block that may be widely made use of in bolstered concrete and strengthened masonry structures. These rebars in many cases are comprised of carbon steel which empower it to be recounted as reinforcing metal or just just reinforcement. Beneath Structural BIM Providers Rebar detailing is known as a self-control of making fabrication or store drawings of metal reinforcement for your design course of action. The location fabrication drawings that may be produced depending on style drawings for reinforcing metal are Rebar Specific drawings. Engineers and Architects make style and design drawings to think of the mandatory strengths based upon the rebar detailing that delivers diameter, bar styles, quantities, size of bars to facilitate your web site for keeping away from delays and wastage thus speeding your entire development system.

Each and every rebar is in-depth representing a shape, length, and diameter depending on the necessities while in the style and design drawing. The Rebar placement are going to be shown in bigger element which suggests the concrete protect, actual area, and Unique method of placement as needed. The rebar information and bar bending schedules will exhibit bar diameter, bar notation, the amount of bars, fat Together with the bars, and length of Each individual bar along with mentioning your entire weight on your entire set of bars put within the drawing. Through the planning of rebar information, the stock lengths of bars are held in check out in order that there isn't any wastage during the substance.

Rebar Detailing and Reinforcement concrete detailing can now be modeled and developed in 3-dimension with the 3D Modelling technological know-how like BIM Modelling Companies. The specialised rebar detailing computer software like Rebar CAD and AutoCAD utilized for this goal may well enable each individual member through the structural engineering to organize styles, document, track, while General Handle.

Possessing understood the critical thought of rebar detailing a place of structural BIM modeling, make it possible for us to make an effort to see the importance of it in your complete design approach is. Some within the motives are:

Great importance of Rebar detailing in Structural BIM Modeling

Although 2D drawings and bending schedules are usually created and provided, the 3D design is also issued to everyone they members beginning with the consulting engineer and contractor departments down to the metal fixers that transpire being about the wander out on-website. The mix of those two turn into Particularly a sensible choice for site staff where internet site limitations or congestion of reinforcements keep on being unidentified until eventually you will find reinforcement and fixation on internet site. For each and every bar, the complete place of repairing is demonstrated inside the 3D model as well as any hindrances or obstructions.

Building detailing reinforcements in 3D on the second system is not merely more quickly but modeling rebar in an exceedingly three-dimensional surroundings assists remove clashes. When modeling It is really doable to visualize if any in the bars Do not correct at the made the decision place, thus determine all these clashes inside the rebar drawings. There exists even the facility to analyze the reinforcement in complete detail as getting a precise detail illustration ahead of it remaining staying requested through the fabricator and sophisticated cages are assembled off-web-site.

When you've got the appropriate rebar detailing Answer out there, a powerful and accurate reinforcement design is usually developed by importing structural calculations while in the structural Evaluation software. With Automation associated modifications are typically mirrored in the 3D rebar detailing along with required updates to drawings and schedules swiftly when changes are made somewhere else in contrast to getting to execute manual changes to 2nd sections and views.

In lieu of based on manual input from paper schedules, the rebar fabricator can extract data directly through the design into the machinery. The concrete pours is usually properly-described in the design with other details like quantities and volumes to verify much more accuracy in managing material deliveries. This enables bigger Command and produce considerably less wastage and reduction of General costs.

Owning 3D specific digital models would not prohibit the edge to the solitary-phase like that of the engineering and detailing section but could be made use of during the phases. Getting reinforcement completely modeled in 3D, the contractor is certain that it will conveniently slot in locations when the time comes for it to become fixed on-web page. The info with the product could be utilized inside the field to permit contractors to carry out a model-based mostly structure by making use of robotic total station units and also monitoring rebar and materials and figuring out where and when they are going to be necessary.

Fixers current on-web-site might be In the product ecosystem for that rebar detailing to accurately understand its software, i.e. precisely what is demanded when and wherever as opposed to relying upon their interpretation of traditional 2D drawings.

The structural engineers can definitely and more quickly create structure reviews, schedules, and drawings out of your 3D product when compared with second layouts, thus maximizing design efficiency. There's a lot more accuracy on price projection according to the rebar portions generated out of your 3D product as They are really more responsible compared to the 2D drawing just take-offs. Not just this the quantities are wholly traceable, enabling comparisons and checks to get carried out simply.

With these explanations, we have the ability to conclude that Rebar Detailing a willpower of Structural BIM Modelling Solutions is one particular while in the important conditions with the General achievement from your undertaking existence cycle. To summarize, getting Rebar Detailing the rebar contractor can concentrate on manufacturing rebars the place there will not be any should really estimate reinforcement necessities for procurements at the web site because of successful 3D designs. The design will depict the necessity for anchors and laps inside drawings thereby guaranteeing structure adequacy together with reducing wastage. The overall squander and time delays are decreased at the website simply because every single one of several form drawings is usually obtainable. Depending on this information the bars may be conveniently fabricated determined by the reo mesh Wollongong designs and number of bars expected.

Mason Gamble Then & Now!

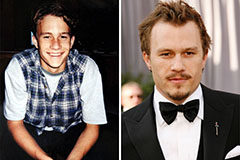

Mason Gamble Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!